Have you heard that this year’s Thanksgiving dinner is expected to be the most expensive one to date? From disposable aluminum turkey pans to the turkeys themselves, prices have increased exponentially—partially due to inflation, but we can also thank global supply chain issues for lighter wallets around the dining table this year.

Kogod professor Itir Karaesmen, who researches how decision-making under uncertainty can affect inventory management and supply chains, explains that the primary challenge in any supply chain is to match the demand with the supply.

“You have to get the right product to the right location at the right time, in the right condition, and at the right price,” she says. “It is difficult to achieve this because the supply chain is a big puzzle with too many pieces that need to mesh together.

“You can’t predict demand for every product at every location with 100 percent accuracy–you also may not be able to predict when supply will arrive at 100 percent accuracy. As a result, you will end up with an excess of inventory or a shortage.”

Kogod professor Chris Parker, who examines how data, analytics, and informational technology can improve operations, explains that supply chain disruptions are not novel to the holiday season. They’re just more sensational. “The media gets really interested when these disruptions impact the holidays by causing gifts to arrive a few days late,” he says.

However, this year, the disruptions are widespread due to ongoing pandemic-induced changes in consumer needs and operational logistics. “The pandemic has led to large demand increases in many products,” Parker explains. “For example, hot tub purchases have increased substantially as people shifted their vacation budgets to home use.

“Firms' ability to supply materials has also been impacted. Some COVID mitigation strategies made it impossible for factories to produce anything, but in the US, we are also having trouble finding enough people willing to work in warehouses or drive items around the country.”

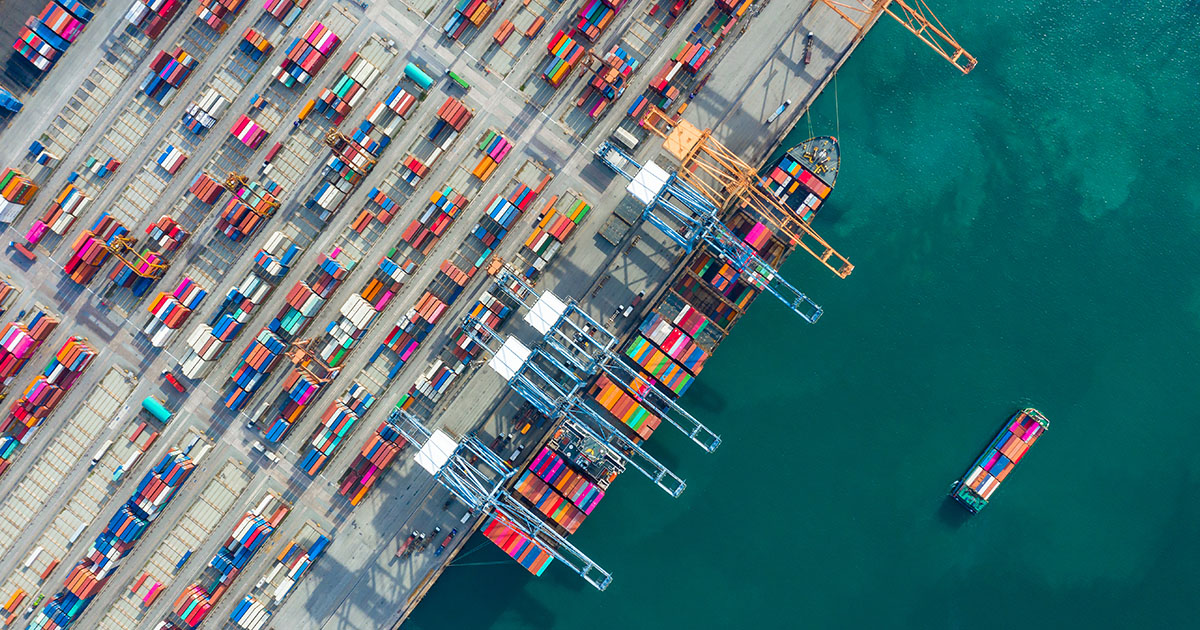

For products coming from overseas, supply chains are experiencing bottlenecks–a now-ubiquitous buzzword. Bottlenecking happens when part of the supply chain is operating efficiently, but other parts can’t act quickly enough to keep materials moving. “We need labor levels to be high enough and to be reliable everywhere in the supply chain,” says Karaesmen. “If any link in the supply chain fails or has a delayed response, then there is not enough buffer capacity or inventory to absorb additional shocks.”

Although this isn’t the first time we are experiencing a supply chain disruption, most issues in the past have been related to natural disasters and isolated to specific regions. Now that we are experiencing this phenomenon globally, we shouldn’t expect to see a “normal” flow in the chain until the second half of 2022.

Consumers can do a few things in the meantime to ease any additional pressure on the already tenuous flow of goods. “A very common response to these shortages is panic buying,” says Parker. “However, this is the exact wrong thing to do. Panic buying sends a signal up the supply chain that demands are increasing, and firms start trying to order more and more. Eventually, when demand calms down, we have a glut of inventory.

“Smooth, simple customer demand can help stabilize the supply chain and remove the bullwhip effect with enough time.”

Eventually, supply chains will become more resilient, but getting there won’t be an even—or easy—process. “Resiliency will allow supply chains to respond quickly to changes in demand or supply, but there is no template that tells you how to become resilient, so every organization will have to develop its own framework and tactics,” says Karaesmen. “Some will start sourcing products locally, some will source from multiple geographic locations, and some will keep higher levels of inventory in anticipation of disruptions.”

Parker advises everyone to make holiday purchases early this year. “Planning in advance can result in lower costs for the exact same products. And as always, don’t be afraid to shop local. A store right around your corner may have just the product you need and could use your support right now!”